What is it for?

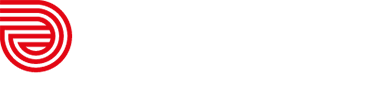

Feeding bowls are designed to contain the different parts which are inserted randomly. They are joined firmly to the vibrating ‘motor’ underneath.

Would you like to know which bowl is more suitable for your parts? Check our Free Test service.

All the different models, from the 225 mm diameter to the 1480 mm diameter, contain a spiral shaped track, starting from the bottom area and ending at the top.

The orienting of the parts can take place by means of different methods and it requires experience, professional skills and talent.

In order to choose structure and materials for the most suitable bowl, different factors must be taken into consideration on the basis of the parts to be oriented.

In Gasco Group we can decide, even only from drawings or images of the parts, which is the right bowl for your machinery.

How and why choose it?

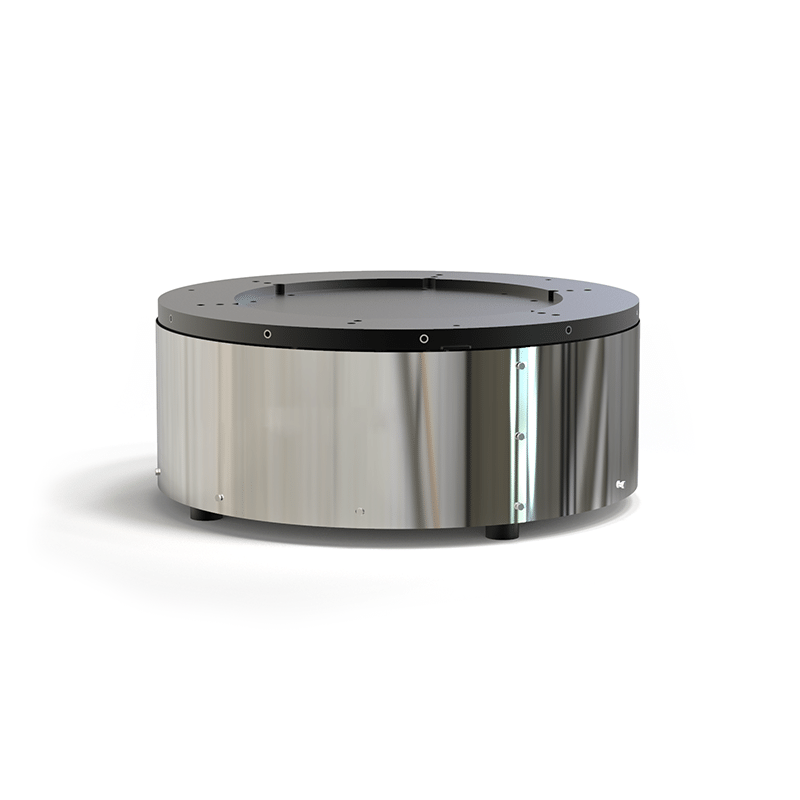

Stepped bowls allow, due to their special design, high loading volumes volumes without the risk of entanglement between part and coils.

Compared to cylindrical and conical bowls, they allow higher conveying speed and frequency.

Customised manufacturing, with internally sloped tracks for particular parts to be oriented, is possible. They are idealfor pipe fittings, taps, thermo-hydraulics and medium-big heavy parts.

Do you need to know how many parts a stepped bowl can contain? Contact us and and we will reply promptly!

Technical features

Materials and customising

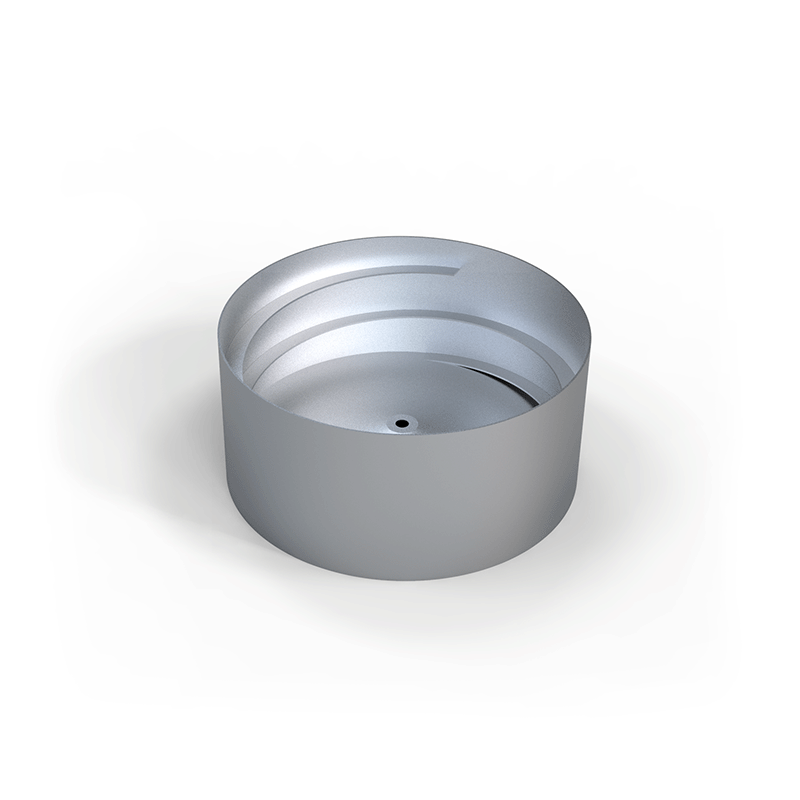

All our standard bowls are manufactured in AISI 304 stainless steel, but they can also be in AISI 316, manganese steel or with screwed tracks in C75 steel.

The standard finishing consists of an internal and external micro shot-blasting, but also but also manual polishing or certified electropolishing can be performed. Internal coatings may also vary, these can be both glued or sprayed coatings with wear-resistant, sound-resistant and oil-proof materials.

With regards to food or medical fields the tracks can be seam welded with relevant certificate (external diameter, coil width and pitch). They can also be modified to be used on other brands drive units.

CLOCKWISE

ANTICLOCKWISE

Scroll to check all the data in the chart ![]()

N.B. In order to access DWG and STEP file you must sign up and proceed to login to download them in the following website section: 3D Downloads.

Models BV46, BV56, BV66 (three-magnet units) have different total heights, to be taken into consideration according to the unit characteristics.

For further informations, please check our catalogue.

This feeding bowl can be combined to these drive units:

Discover the other vibrating containers: