Unicuique suum

To each piece, its system

For decades, our vibratory feeding and orientation systems have been used and appreciated in Italy and abroad, both by end users and automatic machine manufacturers. Seemingly different needs, but the same goals: need for high-performance solutions that are free of glitches and criticalities.

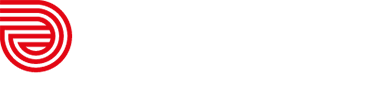

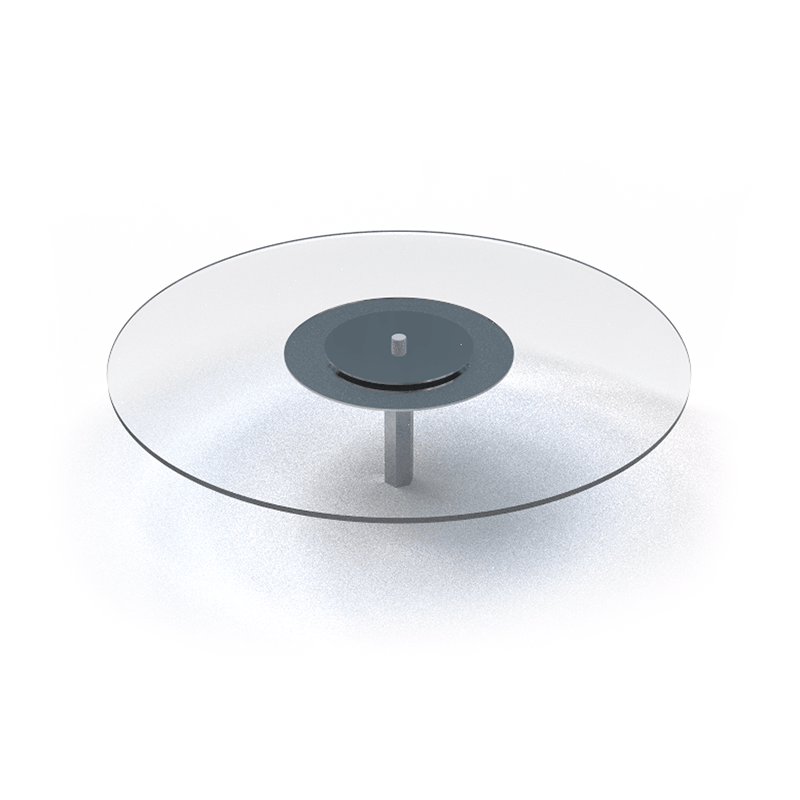

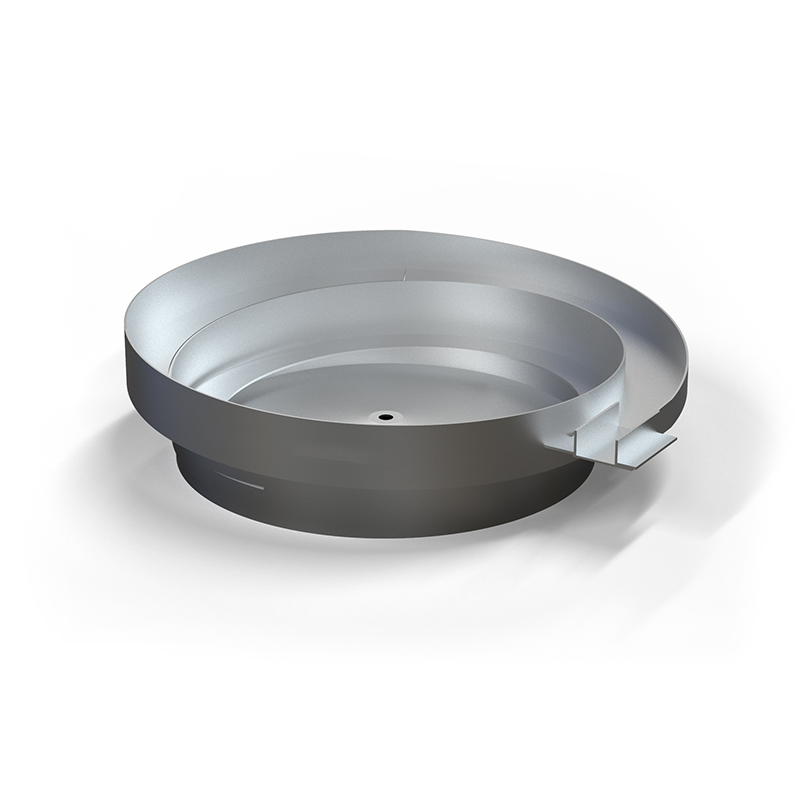

At Gasco Group we have solutions dedicated to the product to be fed and the sector to which it belongs. Each of our systems is taken care of from design to implementation and testing. All solutions designed for the various sectors start from a configuration that is similar:

The added value?

The customization.

Theintervention we operate within the cup,i.e. its 'selection', is intended to ensure that all inserted samples come out in a certain position and at a precise rate.

With over 30 years of experience, we can define with absolute certainty what the characteristics must be to achieve maximum performance for any part in any sector.

Automotive

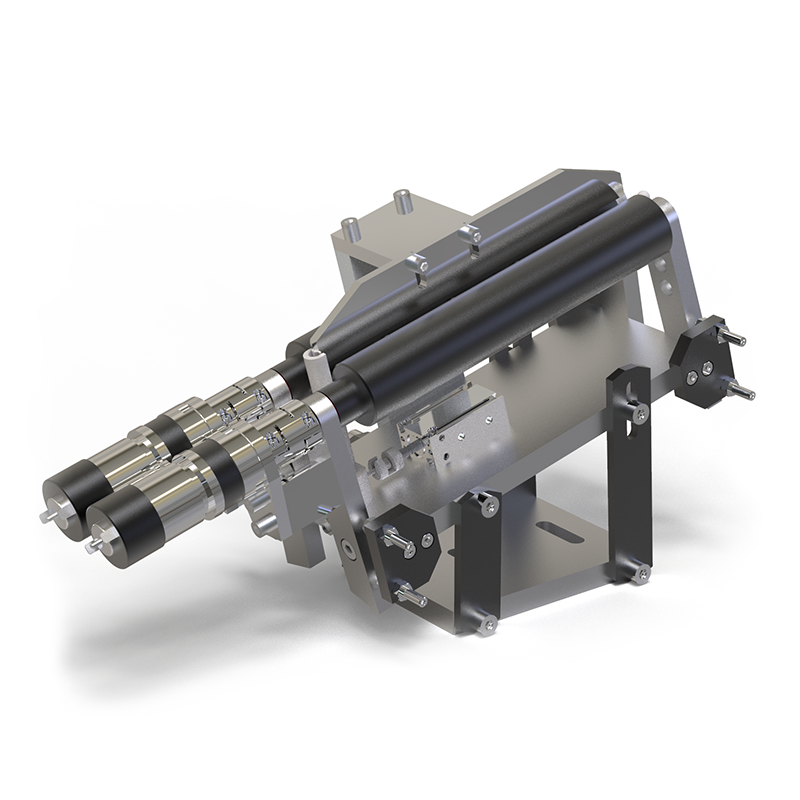

Since the early days, the automotive industry has automated lines using vibratory orientators. The current spread of hybrid and electric cars (EVs) and new technologies in components require increasing levels of productivity and adaptability.

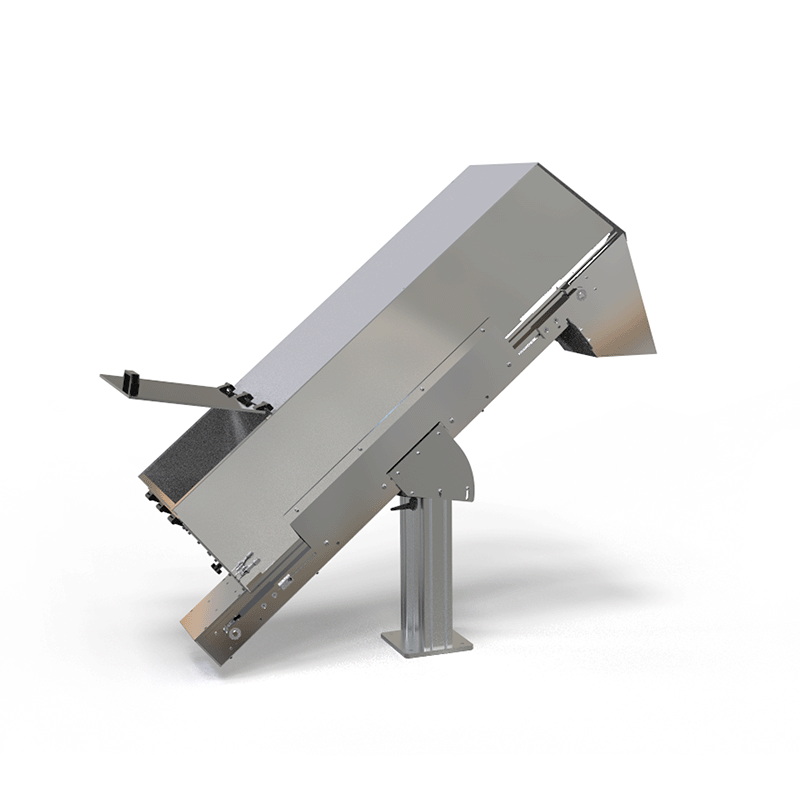

The know-how acquired on various products over the years allows us to offer dedicated and reliable solutions. For example, parts can be oiled, heavy and therefore we can use special coatings inside the cups, or we can use systems with plate elevators or with catenaries. If, on the other hand, dimensional and product quality verification is required, we can provide vision systems to guarantee 100% final inspection.

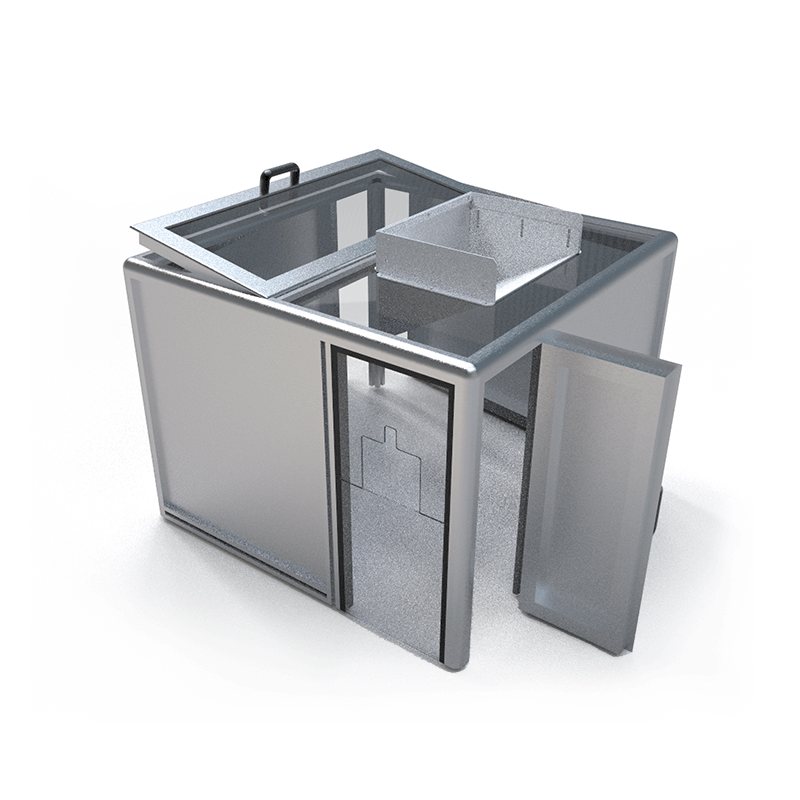

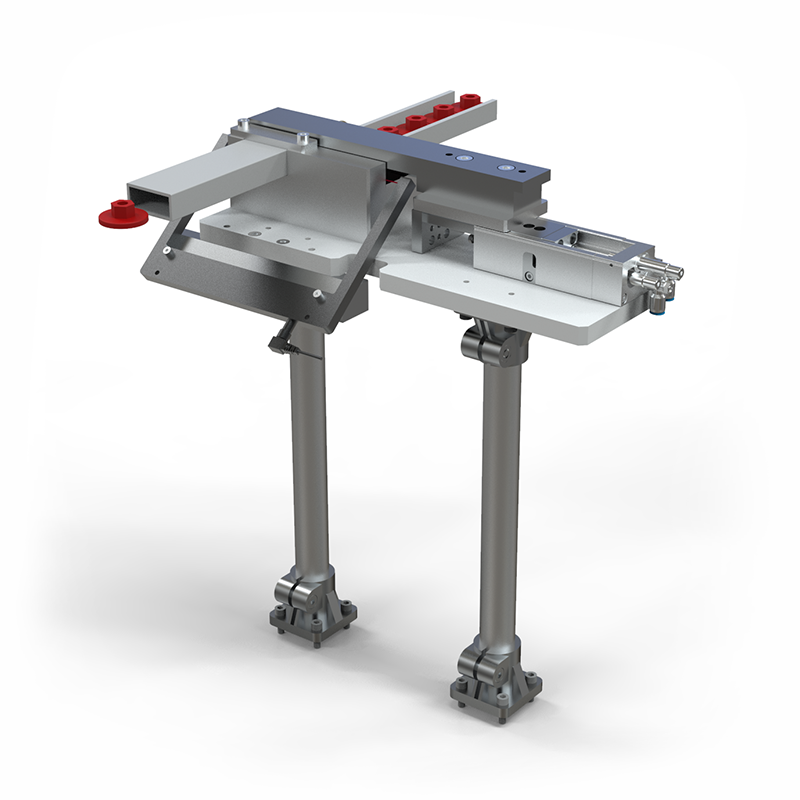

We have standard groups for shooting screws, nuts and bushings for welding islands with robots.

Medical and Cosmetical

The medical and cosmetics sector is very sensitive to aspects of very high productivity and product integrity, being delicate and light. Precisely per evitare opacizzazione o deformazioniwe use special materials and treatments with corresponding GMP certifications. Many solutions are without air blowers, which are rightly considered a critical and expensive element for this type of application. We also use alternative systems to circular vibrators, such as mechanical and centrifugal feeders, or accumulation belts.

We have standard solutionsas complete systems for medical components for use in Clean Rooms.

Electrical Engineering

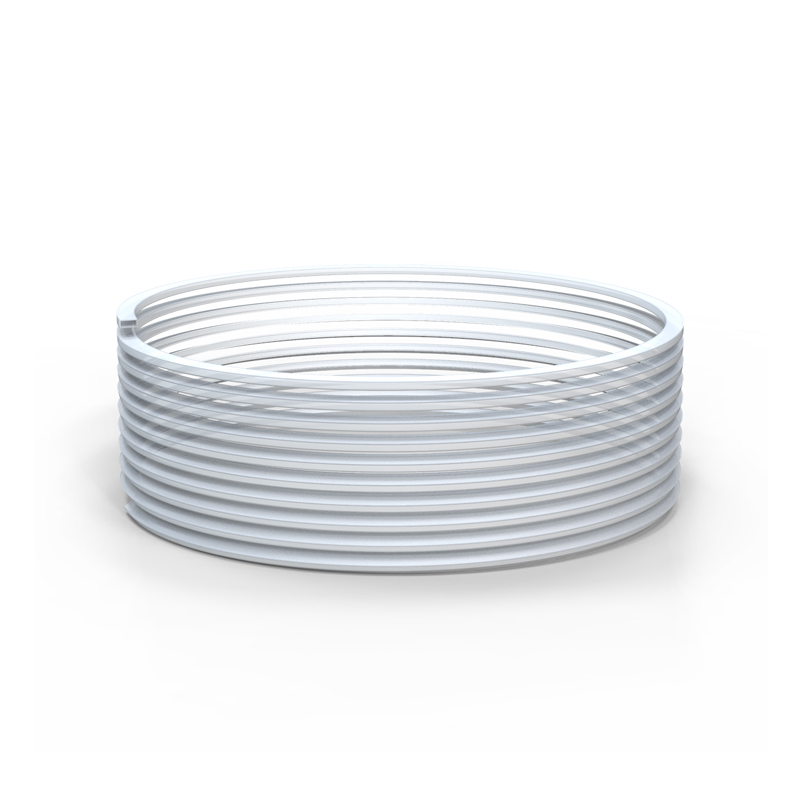

In this sector, products are often light, thin, with complex geometries and easily tangled. Therefore we have targeted solutions, with piezoelectric vibrators or using selections on linear, or conveyor belts.

Also effective is the use of machine-made polyamide containers, which are suitable and effective for parts with small dimensions and tolerances.

For silicone and adherent parts (such as orings or membranes) we also use 3D-printed cups that allow us to have special non-stick shapes.

Wood and Furnishing

Hinges, wooden dowels, screwed sockets, shelf supports are some of the parts found in furniture or doors that are automatically inserted. Gasco Group has been present in this sector for over 30 years and there is not a piece that we have not oriented with our vibrators. This experience allows us to have almost standard vibrators depending on the family of parts to be oriented, with delivery of the finished product in only 5/6 weeks. We often also supply the singularising and eventual firing device to facilitate the insertion of the parts into the wooden panels.

Packaging and Food

Our vibrators in the packaging industry orient the various pieces in single file to enable subsequent counting and inserting. Gasco Group is the absolute leader in Italy as a supplier for manufacturers and users of inserting machines.

Although they are simple vibrators, they are optimally designed to achieve high speeds with relative productivity gains of the machine in envelopes per minute. Thanks also to a continuous dialogue with our customers, we have developed effective devices such as flaps for format change according to the samples inserted, solutions for the evacuation of scraps and dirt, or double adjustments for thinning the pieces along the inner tracks of the cup, all designed to guarantee versatility and correct counting.

Explore Gasco Group components and systems