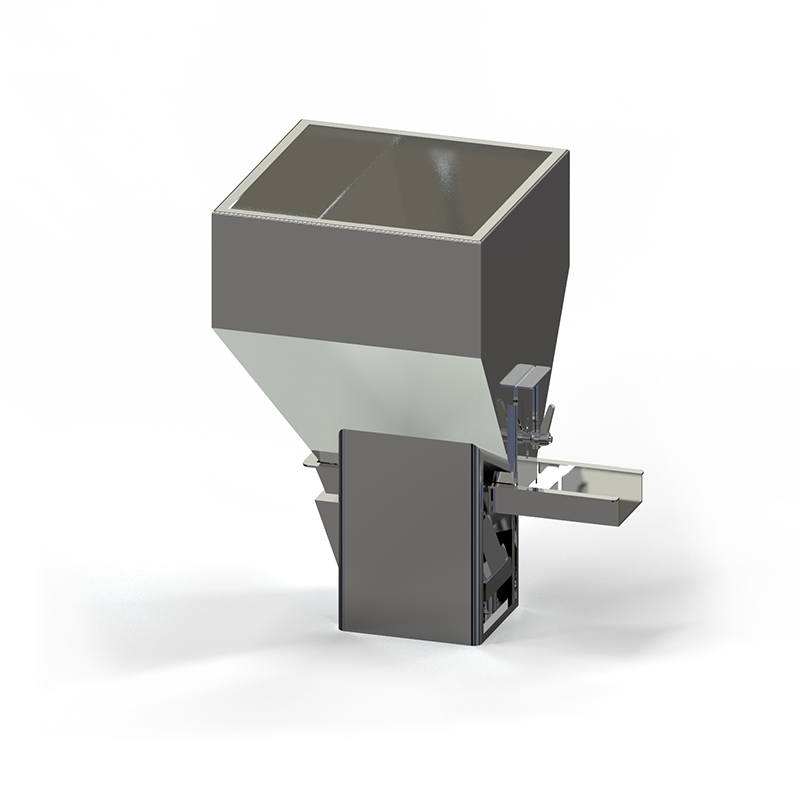

The product

What is it for?

Our hoppers TMD series, sometimes also referred to as “open tank” hoppers, can convey and pre-dose different materials: metallic, granulated, plastic or wood products.

They are suitable for different fields of application:

ndustrial, food, chemical, pharmaceutical, jewellery industries, etc.

They can be combined to:

- Circular feeders/conveyor belts

- Weighing and packaging systems

- Weighing and packaging systems

How to choose?

You can choose one of our models, according to size, weight/volume of your products and expected autonomy.

Other important details:

- Product unloading speed in ton/hr and conveying in metre/min.

- What the hopper is loaded with and where the product is unloaded

- Certified when used in food or pharmaceutical industries

- Environment and field to be employed in

Need help in choosing the most suitable model? Write to us here!

Why choose it?

- Controlled and variable dosing;

- Gamma da 6 Lt. a 85 Lt;

- Prompt delivery, even for batches;

- Easy setting and maintenance;

- Easily adjustable to tanks not in the catalogue;

- Certificates (Food/FDA /UL/Atex) and detailed instructions for use available.

Technical features

Materials and customising

Our TMD series tanks are made of stainless steel (Aisi 304/316). The surface finish can be manual polishing or chemical electropolishing with relevant certificate. Internal coatings can be in glued or sprayed polyurethane (with FDA certificate for food/pharmaceutical industries).

We can also adapt non-standard tanks or according to specific customising requests.

The linear feeders used are the ones with magnets IP class 65/frequency 3000 cycle/min./230V – 50 Hz. and possible UL and Atex certificates.

To be combined:

Fixed or variable frequency controller – Support structure – Level indicator – Fast discharge door - Upper PVC cover - Adjustable dumper.

![]()

Scroll to check all the data in the chart

N.B. In order to access DWG and STEP file you must sign up and proceed to login to download them in the following website section: 3D Downloads.

*Based on dry sand density 1,6

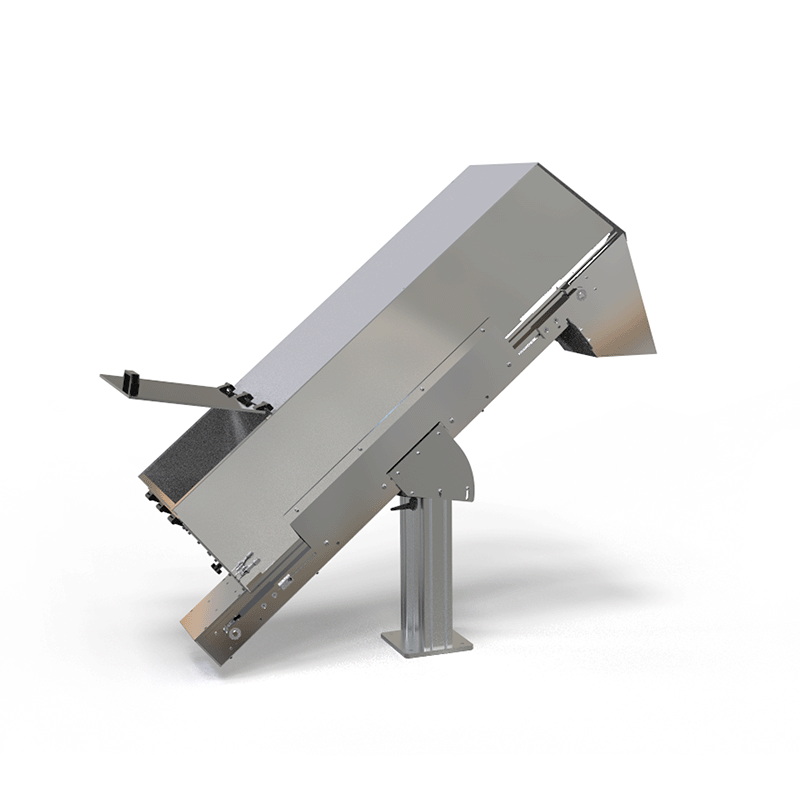

Discover other loading and transport systems: